What is ASIMOV?

The ASIMOV project (AI training using Simulated Instruments for Machine Optimization and Verification) is a collaborative research project running under the ITEA4 programme within the Eureka framework. It was proposed under the Eureka AI call 2020.

Project Problem Statement

High-tech Cyber-Physical Systems (CPSs) are ubiquitous and are playing increasingly important roles throughout our society. Companies, organizations and even full societies depend on their correct functioning. CPSs need to have high up-times and should be easy and economically to use. To fulfil their societal demands, they are becoming increasingly automated, evermore complex and need to be optimised with system and application-specific settings. For such complex systems, finding optimal system settings is a time-consuming and highly complicated task. System suppliers need to assure that CPSs reliably deliver optimal quality in the customers’ environment, without bothering their customers with these complex system optimisation tasks. However, systems are currently optimally tuned before delivery, at installation time and re-tuned during system use when needed by highly skilled staff - a procedure that can easily be hours or even days of work for, e.g., a microscope technician at an electron microscope. Due to growing product diversity, with the demand of customer-specific system configurations, the total time needed to perform such tasks grows rapidly. In those cases where systems interact with an uncertain environment such as unmanned utility vehicles, the task of optimising system settings even needs to be performed continuously to adapt to the changing environment of those systems.

In view of the above trends, ASIMOV’s major industry challenge of interest is formulated as follows:

How to optimise the process of determining optimal system settings for complex (autonomous) high-tech systems in terms of the time and the expertise needed to perform such tasks?

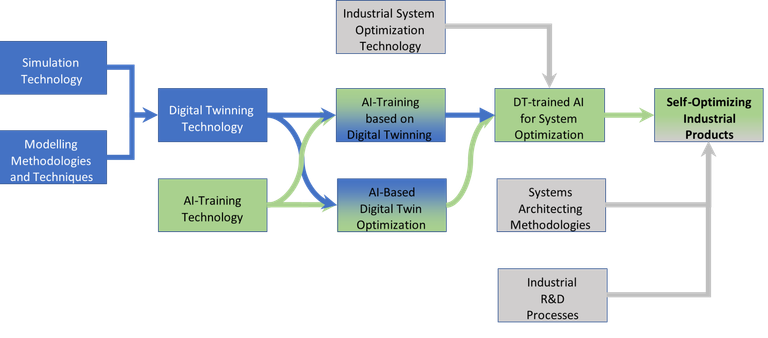

To address this challenge, it is the ambition of the ASIMOV project to develop innovative technologies and software to autonomously and effectively carry out system optimisation tasks by combining Artificial Intelligence-technology and Digital Twinning. Unfortunately, current AI-training technologies require excessive on-system-training time and system data, thereby making them impractical from an industrial and economical perspective. Consequently, major innovations are needed, which lead to the main technical question of the ASIMOV project:

How to enable efficient (continuous) AI-based system optimisation, circumventing the excessive on-systemtraining time and system data required to train a capable AI?

The ASIMOV consortium aims to develop a novel Digital Twin (DT)-based approach for AI-training. It will apply and validate the new technologies in three important industrial use cases: electron microscopy, unmanned utility vehicles and industrial process automation.

Main Research Areas

The consortium, consisting of large industrial parties, leading universities, research institutes, and SME’s with strong AI-expertise, has the ambition to develop new Digital Twinning and AI technologies to create AI-based software that can autonomously perform the system optimisation tasks and deliver system settings during manufacturing, deployment and system usage. This requires a completely novel approach that has to be generally applicable in a wide range of application contexts.

To meet the ASIMOV targets, advances in both AI and DT-technologies beyond the current state-of-the-art will be required in the following areas.

Digital Twinning

- combining multi-modal (multi-engineering/physics) models into DTs that represent a typical system in those aspects that are needed to train an AI for system optimisation/calibration

- methods for fast generation of data, coupled to methods for fast simulation

- methods to validate that the DT is an adequate representation of an actual system for AI-training purposes

- methods/processes to assure consistency between product configurations/versions and the DTs (e.g., methods to detect deviations between the intended and actual operation of the systems, feedback processes to increase the validity of the DTs)

Artificial Intelligence

- AI-training techniques based on DTs and synthetic data, e.g., methods to assure the robustness of the AI to deal with the limitations of DTs

- training AIs with DTs of a limited set of system configurations with the target to configure systems in a wide variety of configurations

- off-line AI-training at the manufacturer’s site, while dealing with configurations in the field; o training AIs to deal with boundary conditions to be satisfied (e.g., for user and system safety, reliability, etc.)

June 2021

Start

May 2024

Planned Completion

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.